7 Types of Plastic

What are recycling numbers, and how to properly dispose of each plastic?

By Catherine Haub

Have you ever looked at the bottom of a plastic cup and noticed the triangle with a number in the middle of it? While most people probably have, they believe that it means that the cup can get thrown in the recycling. That is true for some plastics, but not for all. The number on the bottom of the cup is how one can identify what kind of plastic that cup is. For example, if the number in the middle of the cup is 1, it is PET, which is recyclable plastic. If the number is a 6, you have a recyclable polystyrene cup, but only at specific locations. We know this is super confusing, and very few people understand the chemical degradation of each plastic, which makes sense as to why most people don’t know what can be recycled. Here, we will identify what plastic goes with which number, what each plastic is used for, and whether it can be collected curbside.

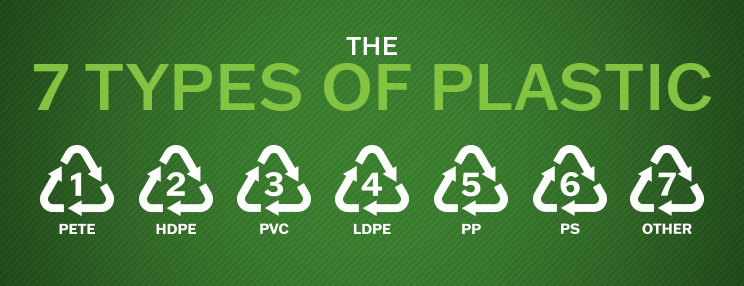

To be able to identify which plastic is which so it can be disposed of properly, you can look to find the number surrounded by a triangle to be able to know the type of plastic. Here are the plastics associated with each number:

- Polyethylene Terephthalate (PET): as stated previously, PET has a resin code of 1 because of its widespread utility and easy reclamation. PET is commonly found in beverage bottles but also in food and retail packaging. PET blocks oxygen well, which helps protect food from spoiling. PET is the most widely recycled plastic in the world and is easily recyclable through curbside recycling [1].

- High-Density Polyethylene (HDPE): HPDE is much stronger than PET, so it can be used to make milk jugs, shampoo bottles, grocery bags, lids, playground equipment, and so much more. It is much high-impact and can reach temperatures up to 248 degrees Fahrenheit! Though it is much thicker than PET, HDPE can also be recycled easily through curbside pickup [1].

- Polyvinyl Chloride (PVC): PVC is the third-most widely produced plastic as it is made in rigid and flexible forms. It can be found in pipes, plastic building materials, plumbing, wiring, and electrical cable. Though it is widely produced, and many efforts have been made to make it more reusable, it is not easily recyclable [2].

- Light-Density Polyethylene (LDPE): this resin is much thinner than HDPE and is often used for plastic grocery bags, six-pack rings, dispensing bottles, plastic wraps, and various containers. With its simple structure, it is easy and cheap to make. While it is reasonable regarding the cost of production, it is not often picked up through curbside programs and is often thrown away, which is why many are going away from using it [1].

- Polypropylene (PP): PP falls right behind PET when it comes to the most produced plastic in the world. This type of plastic is rigid and sturdy, making it great for making Tupperware, car parts, yogurt containers, deli containers, and bottle caps. Though PP is harder to recycle, it can be used more than once due to its high durability, so if your to-go container has a resin code of 5, don’t throw it away and save it for the future [1]!

- Polystyrene (PS): also known as Styrofoam, can be seen in many different forms. PS is used for to-go containers, beverage cups, insulation, egg cartons, and packing material. It is inexpensive and easy to make, causing it to be almost anywhere. If possible, try to stay away from the number 6 code! As stated previously, though, PS cannot be recycled and is often known to be the worst type of plastic for several reasons, but importantly it leaches chemicals when heated [2].

- Other plastic: the number 7 doesn’t include just one type, but all of the materials that don’t fall into the six categories, including barrier materials (like cheese and meat packaging), polycarbonates, bioplastics, PLA, CDs, and much more. Many of these plastics are not recyclable, so avoid the number seven plastic if possible [1].

To summarize, not all plastics are the same; they each have unique qualities and serve different purposes. With all of these types of plastic, it is hard to know which one fits your needs. At Placon, we have a team of experts to help you choose which resin is the best option for you and your product, keeping sustainability and effectiveness high on the list of essential factors. Hopefully, this helped when it comes to choosing what plastics to use and which to avoid.

[1]The 7 Different Types of Plastic<br/> | Plastics For Change

[2]7 Types of Plastic That Are Most Common | PlasticOceans.org

ABOUT PLACON

For 55 years, Placon has been a leading designer and manufacturer of custom and stock plastic packaging for the food, medical, and retail markets. Placon has manufacturing operations in Madison, WI; Elkhart, IN; Plymouth, MN; and West Springfield, MA, and currently ranked in Plastics News 2020 Thermoformers Ranking Top 20. Placon delivers packaging breakthroughs that inspire better engagement between people and products with industry leading innovation and award-winning packaging designs. For more information, visit www.placon.com.