PCR Requirements for Plastic Packaging

Post-Consumer Recycled (PCR) content refers to materials from several types of waste like aluminum cans, plastic bottles, and plastic packaging that are recovered after consumer use from waste channels.

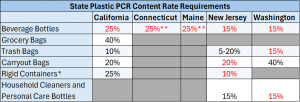

Five States currently have PCR content legislation with the intention of reducing waste, aiding local recycling efforts, and holding producers accountable for what happens to their products after consumer use. This trend continues with several more states having introduced bills in 2025 in relation to PCR and producer responsibility.

Red text indicates the rate is set to change in coming years.

*Some exemptions apply.

**Connecticut’s requirements start January 1st, 2027. Maine’s requirements start January 1st, 2026.

What PCR Can Do for YOU

The good news is that PCR is good for business. Including PCR materials in your products can reduce your Producer Responsibility fees in states with Extended Producer Responsibility laws, especially in states that prohibit the sale of non-compliant products entirely.

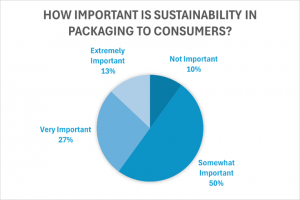

Many companies are increasingly committed to reducing their footprint and investing in packaging producers that utilize PCR to meet company sustainability goals and change consumer needs. Consumers are increasingly prioritizing sustainability and transparency, and it’s reflected in their purchase behavior.

According to a 2023 survey from McKinsey, almost all consumers said environmental impact was at least somewhat important in their decision making when purchasing packaged items. PCR integration can better your brand image and help you stay ahead of changing consumer trends.

Not only is PCR good for business, but also for YOU. Utilizing PCR keeps plastics out of landfills and reduces waste, keeps microplastics out of your water, air, and food, and ensure a greener for yourself and generations to come.

Placon’s Commitment to PCR Material

Placon has long been a sustainability leader in the plastic packaging market. The company introduced PCR content into their stock retail containers in 1991, began in-house extrusion of PCR content in 2002, and opened their EcoStar® PET bottle recycling facility in 2011.

In late 2024, Placon began making all stock food and retail PET products with EcoStar® 50S, a sustainable packaging material made with PCR plastic that meets current packaging requirements in all 50 U.S. states. As regulations change, Placon will adjust the PCR content in the material to meet new requirements, thus helping customers navigate through an ever-evolving regulatory landscape that can be difficult to track and understand.

Placon also offers different levels of PCR content to custom packaging customers to meet any sustainability goals or initiatives they may have. Customers can choose PCR content ranging from 25% to 100%.

Sources

Laws & Requirements for PCR by State

Recycled Plastic Content Requirements – Association of Plastic Recyclers (APR)

Sustainability in packaging: US survey insights | McKinsey

ABOUT PLACON

Since 1966, Placon has been a leading designer and manufacturer of innovative and sustainable plastic packaging for medical, food, and consumer goods markets. Placon has manufacturing operations in Madison, WI; West Springfield, MA; Elkhart, IN; and Plymouth, MN, and is currently ranked in the Top 20 in Plastics News 2024 Thermoformers Rankings. Placon delivers packaging breakthroughs that inspire better engagement between people and products.